Case

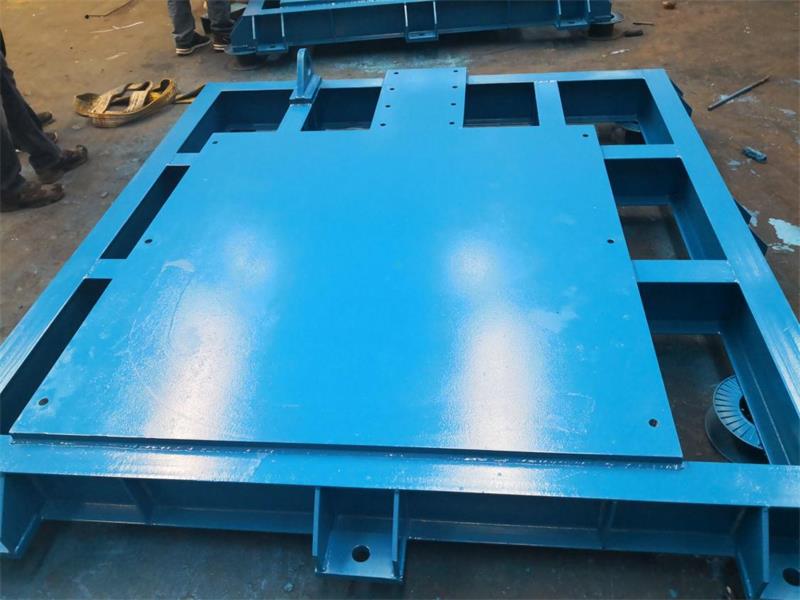

At the end of May, our factory hosted HongKong customer for the inspection of product quality and load testing process. The customer ordered 4 sets of 10 tons electric winches, pulley blocks and 50 tons hooks. This batch winches are non-standard and customized machine used for pulling 40 ton molds for one airport project, so The security and reliability of the winch are highly important and demanding. The winch comes with variable frequency control, and equipped with an audible and visual alarm and additional overload limiter. The winch frame base is installed with a fixed pulley block and a tension sensor. The wire rope is Korean KISWIRE ELEPHANT brand also specially customized. Now that the goods have been finished production, the customer took the engineers to check the load test process and inspect the quality of finished products.

After checking all the finished products, the customer highly praised our quality and welding process, and then according to the customer's request, we arranged the workers to do 1.25 times dynamic load test on all the winches and hooks, and all the load test were successfully passed and load cell all displayed with a pull force of 12500 KN, our products meet the relevant national standards and customer’s requirements.

Our customer is very satisfied with our products and service, and indicated that they will continue to choose our winches and lifting equipmentin future coming projects; After finishing the painting and packaging of the goods, we made the delivery and arranged the truck transportation in early June. Now the customer has already received the cargo, now we think is the job of winch installing and commissioning at the local site of project, and finally the equipment is running normally and goes smoothly. We have also said to our customers many times that we will not only provide high-quality products, but also continue to do a good job in after-sales service and continuously improve customer satisfaction.